A spectrum analyzer measures the size of an input signal versus frequency over the full frequency selection of the instrument. The main use is to assess the ability of the spectrum of known and unknown signs. The input signal an digital spectrum analyzer measures is electrical; however, spectral compositions of different signals, such as acoustic waves and optical light waves, may be viewed through the use of an proper transducer. Optical spectrum analyzers also exist, which utilize direct optical techniques such as a monochromator to make measurements.

By analyzing the spectra of electrical signals, dominant frequency, power, distortion, harmonics, bandwidth, and other supernatural components of a signal can be observed which are not easily detectable in time domain waveforms. These parameters are useful in the characterization of electronic devices, such as wireless transmitters.

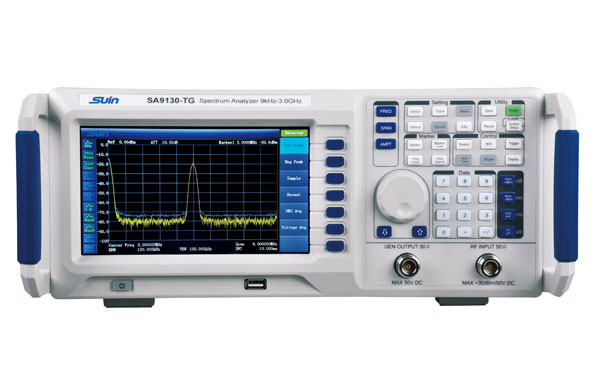

The screen of a high-performance spectrum analyzer has frequency on the horizontal axis and the amplitude exhibited on the vertical axis. To the casual observer, a spectrum analyzer looks like an oscilloscope and, in fact, some lab instruments can operate either as an oscilloscope or a spectrum analyzer.

Jul. 10, 2025

Common Uses and Types of Signal GeneratorsJun. 13, 2025

Power Quality Analyzers: SA2100, SA2200, and SA2300 – Which One Fits Your Workflow?May. 14, 2025

Stopwatch Calibrator Uses in Aerospace, Automotive and Labs