Power Quality – What does Class A mean?

Power quality monitoring is usually not a problem until system failures, equipment failures that lead to production disruptions, data loss, IT interruption, and even power outage occur. Generally the fault location problem is time-consuming because their cause is not always immediately identifiable. In addition, once the failure occurs, it is inevitable to cause losses, while these failures can be detected in time by means of monitoring in advance so as to corresponding measures could be taken to avoid losses.

Power quality is defined in EN 50160, which describes the voltage characteristics in the supply network. However, IEC 61000-4-30 Edition3 defines the required accuracy to measure grid quality. The standard distinguishes between different device categories. In the situation of Class A (A=Advanced), measurement values obtained from different devices manufactured by different supplier are comparable and are always used when accurate measurements are required. This standard provides reliable, repeatable and comparable results that can be used for billing purposes.

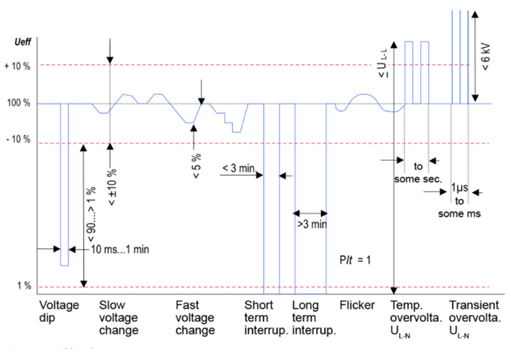

The following measurements are standardized by IEC 61000-4-30 Edition 3 and are mandatory for Class A device:

■ Power frequency

■ Magnitude of the supply voltage

■ Voltage unbalance

■ Voltage Swell/dip/interruption

■ Fast voltage change

■ Harmonic/inter-harmonic THD

■ Flicker

■ Power signal on the supply voltage

*ClassA-SA2200

Transient can also be measured as an option. In a 50Hz grid, the root-mean-square (RMS) value of the supply voltage is measured over 10 cycles. The measured time intervals must be continuous and must not overlap with adjacent intervals. The measurement error shall not exceed 0.1% of the rated supply voltage value under the conditions described in this standard.

The difference between Class A and Class S

As a Class A device, it requires very high measurement accuracy, but a Class S device (S=Survey) required much lower on it — the data and events are only qualitatively recorded, which requires less measurement accuracy. In addition, Class S devices do not have to measure as much as Class A devices.

Class S devices must measure below parameters:

■ Power frequency

■ Magnitude of the supply voltage

■ Voltage unbalance

■ Voltage Swell/dip/interruption

■ Fast voltage change

*Class S-SA210

Overview – Comparison between Class A and Class S

| Test as IEC61000-4-30, Edition 3 | Class A | Class S |

| Power frequency | √ | √ |

| Voltage Magnitude | √ | √ |

| Voltage unbalance | √ | √ |

| Voltage Swell/dip/interruption | √ | √ |

| Fast voltage change | √ | √ |

| Harmonic/inter-harmonic THD | √ | × |

| Flicker | √ | × |

| Power signal on the supply voltage | √ | × |

| Transient | option | option |

Power Quality Monitoring:Voltage Event

Jul. 10, 2025

Common Uses and Types of Signal GeneratorsJun. 13, 2025

Power Quality Analyzers: SA2100, SA2200, and SA2300 – Which One Fits Your Workflow?May. 14, 2025

Stopwatch Calibrator Uses in Aerospace, Automotive and Labs