How to set up the high sensitivity of the Spectrum Analyzers to facilitate the observation of small signals?

A: first, set the corresponding center frequency sweep width (span) and reference level according to the size of the small signal under test;Then, the attenuation value is gradually reduced in the absence of any overload warning in the spectrum analyzer.If the SNR of the measured small signal is less than 15db, RBW will be gradually reduced. The smaller RBW is, the lower the base noise of the spectrum analyzer will be, and the higher the sensitivity will be.

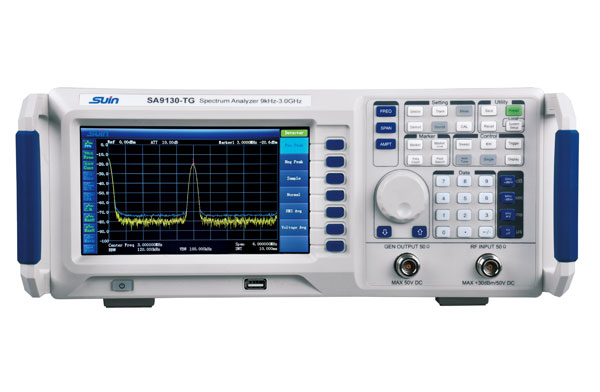

If the spectrum analyzer from Spectrum Analyzer Supplier has pre-amplifier, opening pre-amplifier and pre-release can improve the noise coefficient of the spectrum analyzer, thus improving the sensitivity. For small signals with low signal-to-noise ratio, it can reduce VBW or adopt trajectory average to smooth the noise and reduce fluctuation.

It should be noted that the measurement result of the spectrum analyzer is the sum of the external input signal and the internal noise of the spectrum analyzer. In order to make the measurement result accurate, the signal-to-noise ratio is usually required to be greater than 20db.

Jul. 10, 2025

Common Uses and Types of Signal GeneratorsJun. 13, 2025

Power Quality Analyzers: SA2100, SA2200, and SA2300 – Which One Fits Your Workflow?May. 14, 2025

Stopwatch Calibrator Uses in Aerospace, Automotive and Labs